Biomass: Powering India’s Sustainable Energy Future

As the global community transitions towards more sustainable energy sources, bioenergy has emerged as a promising solution, particularly for countries with substantial agricultural resources like India. With its vast reserves of organic waste and residues, India holds significant potential to transform biomass into clean, renewable energy. This blog delves deeper into various biomass conversion technologies and the opportunities they present for India to harness its resources for sustainable development.

The Growing Need for Sustainable Energy in India

India’s increasing population, rapid urbanisation, and industrial expansion have dramatically escalated energy demands. Traditionally, this growing need has been met through fossil fuels, leading to soaring import costs and contributing significantly to carbon emissions. The environmental and economic challenges posed by such reliance have spurred the Indian government to set ambitious targets, such as producing 5 million metric tonnes of green hydrogen annually by 2030.

One of the most promising technologies to achieve these targets is biomass gasification, which offers a renewable and low-carbon solution to meet India’s energy requirements. Biomass can be converted into multiple forms of energy, such as biogas, ethanol, and biodiesel, which are crucial for transportation, electricity generation, and heating. Unlike fossil fuels, bioenergy is considered carbon-neutral, as the carbon dioxide (CO2) released during its combustion is offset by the CO2 absorbed by plants during their growth.

The Role of Biomass Feedstocks in Energy Production

Biomass feedstocks are organic materials derived from agricultural residues, forestry by-products, purpose-grown energy crops, and organic waste (e.g., municipal solid waste, sewage sludge). These feedstocks represent a rich, underutilised source of renewable energy that could contribute significantly to India’s energy mix. However, one of the key challenges is optimising the energy density of these raw materials. Wet biomass, for instance, contains high moisture levels, which reduce its energy efficiency and require additional energy for evaporation.

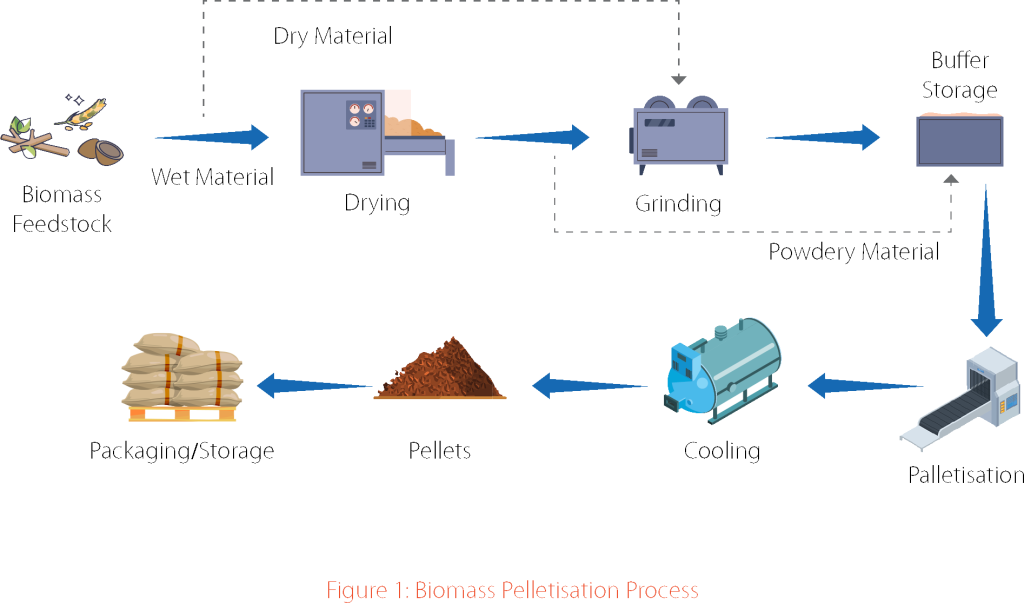

The solution lies in biomass pelletisation. This process involves drying the biomass to reduce its moisture content to 10-15%, followed by grinding to reduce the size of the material for easier compression. The final step is the pelletisation itself, where the material is compressed against a heated die. This step softens the biomass’s natural lignin, which acts as a binding agent, forming dense energy pellets. These pellets can then undergo torrefaction – a thermal process that further enhances their energy density, combustion properties, and shelf life.

The Indian government has introduced policies to promote co-firing of biomass pellets in coal-fired power plants. Substituting up to 20% of coal with biomass in such plants not only reduces carbon emissions but also increases farmers’ incomes by creating a viable market for agricultural residues.

India’s Untapped Biomass Potential

India’s annual availability of biomass feedstock is immense, totalling approximately 308 million tonnes (MT). This includes 122.27 MT of rice straw, 109.52 MT of wheat straw, and 51.15 MT of coarse cereals, in addition to other agricultural residues. Moreover, the country has vast cultivation areas for crops like sugarcane, oilseeds, cotton, and jute. Utilising these diverse resources effectively could revolutionise India’s energy landscape.

For instance, ethanol can be produced from sugarcane bagasse (the fibrous residue left after juice extraction in sugar mills), with an impressive conversion efficiency of around 70%. Each tonne of bagasse yields approximately 250 litres of ethanol, highlighting the productivity of bioenergy processes. Given that India produces around 399 MT of sugarcane bagasse annually, this feedstock alone could generate nearly 100 billion litres of ethanol, offering immense potential to reduce reliance on imported fossil fuels.

Key Biomass Conversion Technologies

Several technologies have been developed to convert biomass into energy, each offering unique benefits. Below are some of the key technologies used in bioenergy production:

- Gasification:

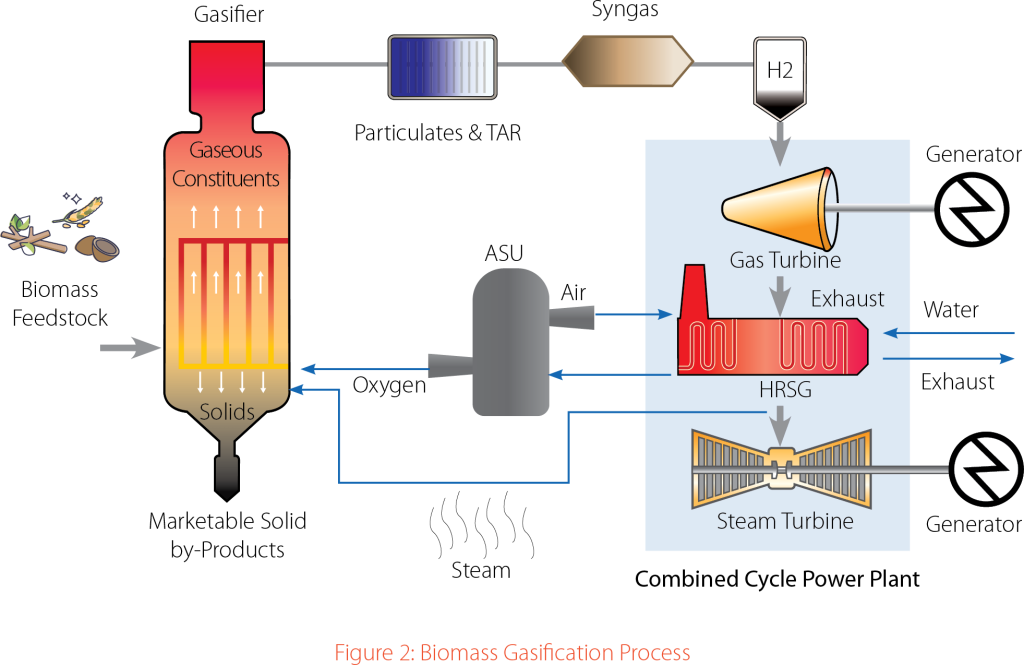

Biomass gasification is a process that converts organic materials into syngas (a mixture of carbon monoxide, hydrogen, and other gases) by heating them in a low-oxygen environment. The two primary types of gasification are:- Thermal Gasification: In this process, biomass is heated in the presence of limited oxygen to produce syngas, which can be further converted into electricity, heat, and even biofuels such as ethanol and methanol.

- Oxy-fuel Gasification: Here, oxygen is used instead of air, resulting in a higher concentration of carbon monoxide and hydrogen in the syngas. This is particularly useful for producing green hydrogen – a key component of India’s future energy plans.

- Pyrolysis:

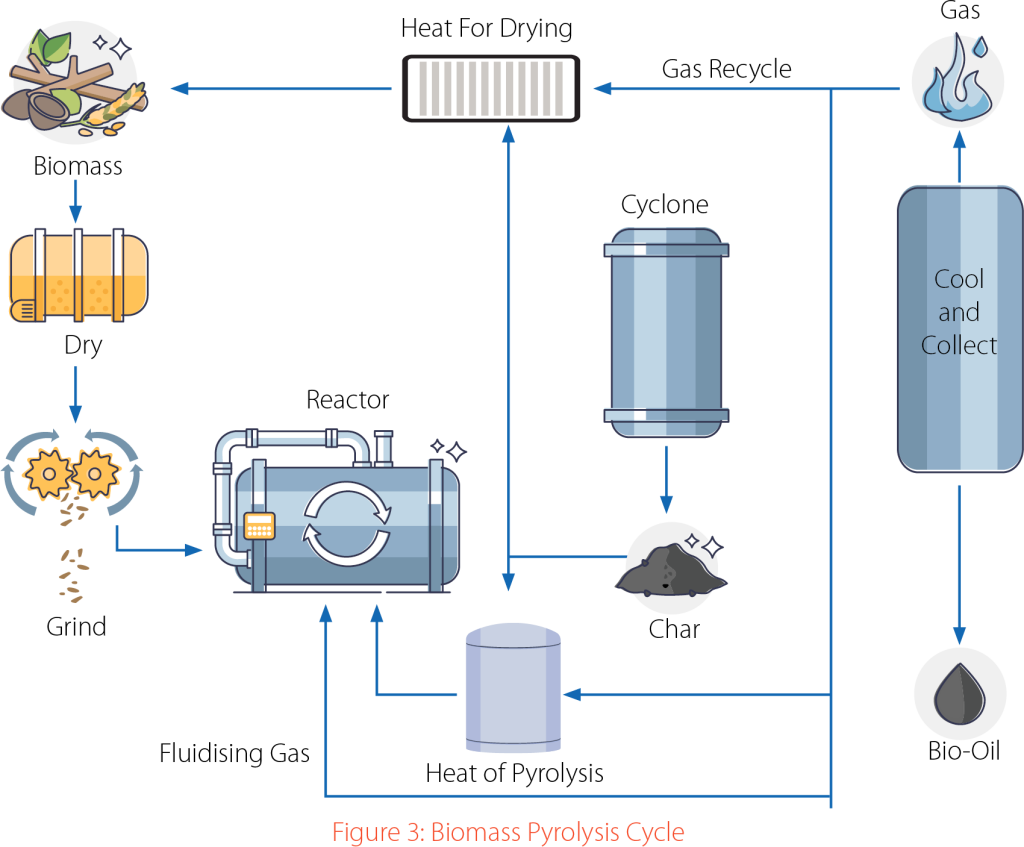

Pyrolysis involves heating biomass in the absence of oxygen, breaking it down into bio-oil, biochar, and syngas. The bio-oil produced can be refined into hydrocarbon fuels like diesel, gasoline, and jet fuel. Pyrolysis is a versatile technology, providing options for both solid fuel and liquid fuel production, depending on the operating conditions.

- Plasma Gasification:

Plasma gasification utilises extremely high temperatures (above 2,000°C) to convert organic materials into syngas or other valuable products. This advanced technology is efficient in waste-to-energy conversion, producing high yields of syngas, which can be further processed into hydrogen or other fuels.

Case Study: Ethanol Blending and its Impact in India

To reduce the environmental impact of fossil fuels, the Indian government launched the Ethanol Blending Programme (EBP), which mandates a minimum 10% blending of ethanol with petrol. This target is set to rise to 20% by 2025. Presently, the majority of ethanol for blending is derived from sugarcane, significantly boosting demand for this crop.

In states like Maharashtra, where sugarcane cultivation is abundant, the potential for ethanol production from sugarcane bagasse is particularly high. A hypothetical ethanol production facility could process 100,000 tonnes of bagasse annually, yielding around 250 litres of ethanol per tonne. Such projects not only reduce carbon emissions but also offer excellent returns on investment (RoI) with a payback period of less than five years. Furthermore, these projects create employment opportunities in rural areas, contributing to the socio-economic development of local communities.

Takeaways: Unlocking India’s Bioenergy Potential

India’s abundant biomass resources present a golden opportunity for addressing energy security challenges while fostering environmental sustainability. By harnessing agricultural residues, forestry by-products, and organic waste, the country can diversify its energy portfolio, reduce its carbon footprint, and stimulate rural development. However, the full potential of bioenergy can only be realised through technological innovation, policy support, and collaboration between government, industry, and academia.

Tata Consulting Engineers (TCE) has been actively involved in advancing India’s bioenergy sector. TCE’s participation in establishing one of India’s first second-generation (2G) bioethanol plants demonstrates its commitment to sustainable energy solutions. This pioneering effort provides invaluable insights into the commercialisation of advanced bioethanol technology and reinforces TCE’s role in driving India’s renewable energy agenda.

With strategic investments and the right policy framework, India is well-positioned to unlock the potential of bioenergy, paving the way for a greener, more resilient future.

References

- Indian Scenario of Biomass Availability and Its Bioenergy-Conversion Potential (researchgate.net)

- An Introduction to Bioenergy: Feedstocks, Processes, and Products – ATTRA – Sustainable Agriculture (ncat.org)

- Ethanol Production from Sugarcane: An Overview (researchgate.net).

- Punnathanam, V., Shastri, Y. Optimization-based design for lignocellulosic ethanol production: a case study of the state of Maharashtra, India. Clean Techn Environ Policy 24, 863–886 (2022). https://doi.org/10.1007/s10098-021-02227-4