Dynamic Study of Integrated Steam Systems in a Large Process Plant

Combined heat and power plant which is generally referred as cogeneration-plant produce both power and steam is installed to meet process plant requirements. Any change of demand in either power or steam would affect the other. In progressive process plants interconnection of units generating steam at various pressure levels is not uncommon. However, this makes the operation of the system more complex to handle especially during upset conditions. This situation can be handled effectively by carrying out dynamic study of the entire steam system to operate the plant in a safe and at optimum level within the constraints, if any.

Normally, in cogeneration plants steam produced will form a header and supply to process plant located within the complex. Every cogeneration plant is unique as its type, configuration, pressure levels at turbine port; fuel etc. varies to suit the multiple demands of the process plant. As such optimum design of a cogeneration plant and the steam header needs thorough understanding of power and steam generation and also process plant requirements under various operating conditions including abnormal/ emergency conditions.

Such variations in process demand with multiple plant configurations pose a huge challenge in sustaining the power generation at the occurrence of an abnormal operating condition and also to normalize the system quickly, economically and with highest reliability. To effectively deal with this situation, understanding of pressure dynamics and quantification of steam pressures during transient conditions and proper control measures are essential.

In one of the projects engineered by TCE, as part of expansion program of existing Alumina refinery, additional power and process steam were required to meet the demand of expansion program.

The captive power plant associated with the Alumina refinery plant currently generates 2200 MW (nominal) of power from eight gas turbine generators (GTG) and four steam turbine generators (STG) in addition to one more GTG operating in simple cycle mode. The steam required for the process is met by generating steam internally in the process plant.

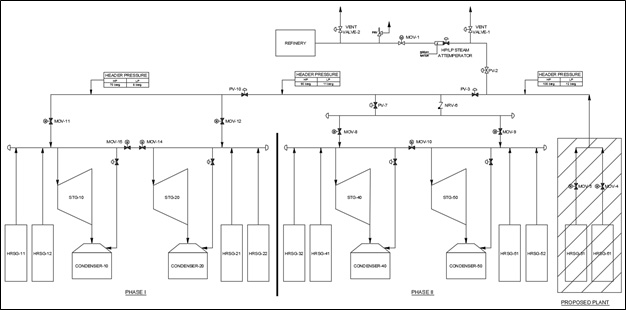

To cater to the additional power and steam demand of the process plant due to its proposed expansion, it was decided to install one new GTG with one new heat recovery steam generator (HRSG); additionally one more HRSG also would be installed behind the existing GTG which is presently operating in simple cycle mode. Also it is proposed to interconnect all the steam headers at both high pressure (HP) and low pressure (LP) levels as shown in the schematic diagram below to ensure uninterrupted steam supply to the process plant.

As the steam is drawn from the common steam header any abnormal operating condition will reflect immediately on the steam pressure dynamics.

TCE first studied the FEED document prepared for the expansion project and developed a base model using Aspen Hysis, a dynamic modelling software. A total of 55 probable abnormal operating scenarios that could affect the steam header pressure were identified and simulated.

Based on the simulation analysis, diverting of steam using automatic control valves, additional automatic steam venting devices were proposed. Also steam venting devices capacities were finalized in order to limit the steam pressure variation and to improve the system reliability. Measures to ramp-up and ramp-down the cogeneration plant was also recommended to minimize the steam venting.

Analysis of dynamic behavior of such interconnected steam system with multiple generators and users require thorough understanding of the processes. Successful execution of the projects involving steam dynamic analysis amply demonstrates TCE’s capability and expertise in handling such complex tasks.