Instrument Interface with Non-Metallic pipelines

Non-Metallic pipelines

Fiber reinforced plastics (FRP) is a composite material made of a polymer matrix reinforced with fibers. Glass, Carbon, Aramid etc. can be used as a fiber of the composite and the Polyester, Vinyl ester or Epoxy plastics acts as a thermosetting resin.

Fiberglass (GRP) is one type of FRP. Fiberglass or GRP is a composite material made from glass fibers and uses polyester, vinyl, or epoxy as the polymer. In a nutshell, if glass fibers are used along with plastic to prepare the composite material then, it is known as GRP.

They are used because of its lightweight, temperature resistant, strong, and highly resistant to chemicals and corrosion property. These pipes are easy to install and rarely need repair because of their low maintenance.

However, these pipelines can be used upto maximum temperature of 275 °F

Interfacing Instruments / valves with Non-metallic pipes .

For any plant or system to operate efficiently and safely instruments/valves needs to be provided on the pipelines. Providing instruments/valves on metallic piping is very common in any plant or system. However, installing instrument/valves on non-metallic pipes is not conventional and needs additional efforts and engineering to have smooth operations.

Flanged Process Connection

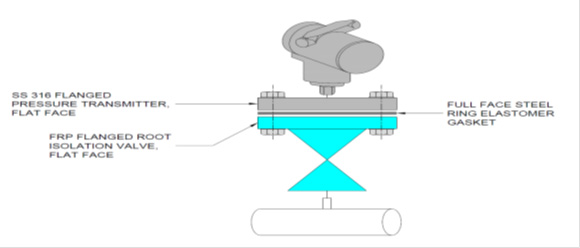

- For the installation of instruments on FRP pipeline with isolation root valve, usually the flanged FRP root valves comes with a flat face (FF). Flat face FRP flanges must be bolted to flat face companion flanges of the Instrument with full gasket sandwiched between the two. So, care must be taken while procuring instrument that flange type specified is flat face. (Refer Figure 1)

Figure – 1

- For the installation of instruments on FRP pipeline without the isolation root valve, care is to be taken to understand what end connection is provided by the piping. Generally piping provides flanged connection and there are two ways to provide flanged connection as mentioned below:

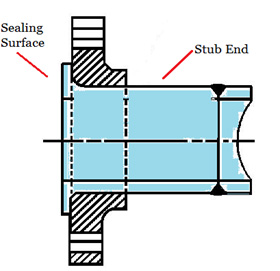

– The Stub end is used in combination with the FRP flanges in such a way that the sealing surface is on the stub end. This kind of facing is like the RF flange arrangement. Hence the companion flanges of the Instrument are to be considered with a raised face (RF). (Refer Figure 2)

Figure – 2

– The FRP stub end flanges are also available with flat face (FF). This flange must be bolted to flat face companion flanges of the Instrument with full gasket sandwiched between the two. (Refer Figure 3)

Figure – 3

While procuring instrument with flanged end connection care must be taken to match with above 2 types of FRP flanges.

- Gasket for Metallic-GRP pipeline interface :

In order to have reliable flange sealing, generally steel ring elastomer gaskets (Refer Figure 4) are used. Gasket material should match with pressure, temperature, chemical resistance requirements. PTFE-envelope type gaskets (Refer Figure 5) should be avoided for large size and high pressure.

Figure – 4

Figure – 5

Threaded connection for instruments on the FRP lines are not recommended as the material of construction for instruments / valves / fitting are mostly metallic. While installing this instruments / valves / fitting on FRP pipes with threaded connection, if more torque is applied it may damage the FRP pipe threads and will lead to leakage from this connection.

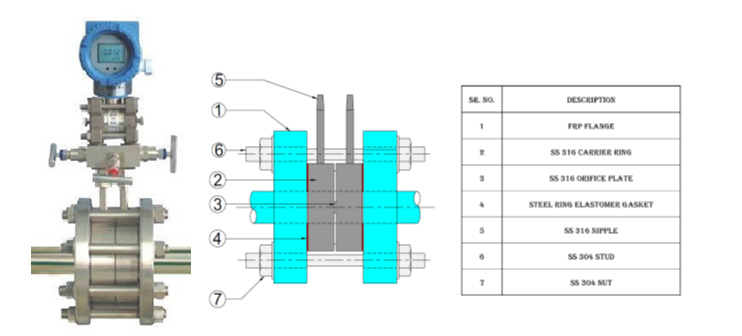

The Fig-6 below shows the typical mounting of orifice plate on FRP line. The orifice plate is mounted between the carrier ring. Carrier ring orifice plate block is sandwiched between FRP flanges with through & through bolts.

Figure – 6