Use High Strength Precast Concrete Spun Piles

Abstract

High strength precast spun concrete piles have an economical advantage over conventional solid concrete friction piles in terms of quality, Strength and speed of construction. Moreover, these piles are best suited where there is no requirement of high shear and tension resistance and less active seismic zones where load transfer is envisaged through skin friction.

Introduction

TCE has been providing detail engineering services for green and brown field projects which include ISBL, OSBL and Infrastructure facilities. As part of detail engineering services, TCE studies soil parameters and recommends most appropriate foundation solution.

On one of the ongoing project overseas, after completing the soil investigation, it was observed that load carrying capacity of the soil is very poor as compared to the load of the building. Depending upon the soil parameters, N-values and Bore log data, friction piles were recommended by TCE for foundation system.

Type of Friction Piles

Since the superstructure load is being transferred to ground using friction between soil and concrete surface, TCE recommended adopting Pre-cast (pre-stressed) spun concrete pipes as friction piles. Moreover, the site is located in non-seismic active zone and there was no requirement of high shear and tension resistance, which is most conducive site condition to adopt high strength, pre-tensioned spun concrete pile foundation. The pile capacities worked out considering ultimate skin friction and ultimate end bearing with factor of safety.

Pre-stressed Concrete Circular Spun Piles are used all over the world especially in south east Asia. High strength precast spun concrete piles has an edge over piles that are cast at site in terms of superior quality and strength. The centrifugal compaction process is used to manufacture these piles ensuring uniform quality & strength using of higher grade of concrete such as M50, M60, M80, etc.

These piles can be manufactured in any length (Max length 12m) as per the design. The steel end plates are provided in each length of pile manufactured for splice connection of two lengths. Moreover, these piles can be driven with using conventional hammer and hence need for any special driving tool is eliminated.

High Strength Precast Spun Concrete Friction Piles

High strength precast spun concrete piles are shop manufactured and tested under strict quality control. After casting, the piles are cured using steam. When the concrete reaches the desired strength, the piles are de-shuttered and tested for quality compliance. The piles can be transported to site after ensuring quality compliance for driving at locations as marked in the construction drawing. Piles can be transported after a week after completing all the quality checks.

These piles are driven using environment friendly tool such as hydraulic jacking equipment which is less noise & air polluting and produces less vibration during the driving of the piles.

Pre-stressed concrete provides higher bending moment capacity compared to conventional reinforced concrete piles e.g. minimum concrete strength at transfer of pre-stress is 30 N/sq.mm at 28 days – Grade 80 pile 80 N/sq.mm.

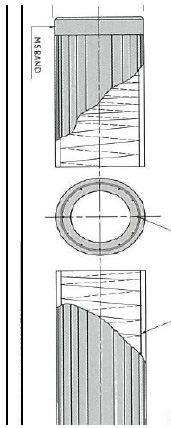

Refer Fig-1 for starter and extension pile along-with salient features. The starter pile is the lowermost part of the pile length that is driven first and then the required length of pile is achieved using extension piles. Depending upon the depth to be achieved below ground, the lengths of these portions are decided.

Fig-1: Starter and Extension Pile

- Can be manufactured in length 10 to 12m.

- Lower cost due to lesser unit weight

- Higher grade of concrete (M60, M80) facilitates the pile driving in hard strata.

- Denser concrete and increased concrete strength

- High corrosion resistant.

- Uniform Quality achievement

- Saving in construction time is achieved with speed of construction due to higher manufacturing capacity.

- Minimized infrastructure at site such as casting yard etc.

Comparison of Cast in-situ Concrete and High Strength Precast Spun Concrete Pile

| Sr. No | Description | Precast Spun pile | Cast in-situ pile |

| 1 | Piling Schedule | Approx. 10 piles per day with using one rig; so saving in approx. 20 to 25% cost | Approx. 2 to 3 piles per day with one rig |

| 2 | Integrity test | Each pile is factory tested with high quality control and hence no need to conduct pile integrity test at site. | Pile integrity test needed for every pile at site after installation. |

| 3 | Strength | Higher load carrying capacity due to higher strength than cast in-situ piles, | Lesser strength than precast spun concrete pile |

| 4 | Environment Protection | Maximum site cleanliness as pile boring is avoided | Due to in-situ pile boring activities, site is messy. |

For the on-going project, contractor has driven 380 piles (out of total 439) in 30 days using two rigs working in tandem i.e. average 13 piles per day.

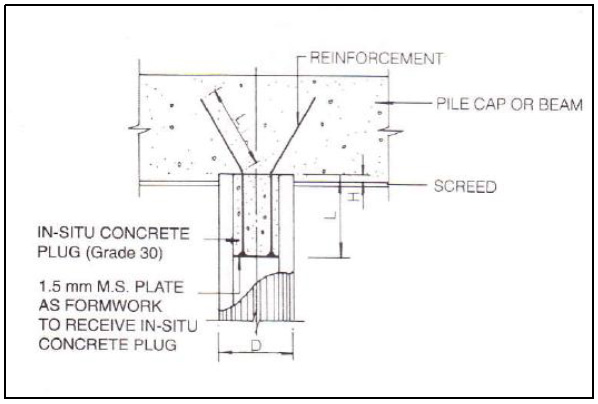

Bonding Piles in-to Pile-Cap: The spun pile and Pile cap are bonded together with the help of in-situ concrete plug as shown in the Fig.2 below. The pile need not to be stripped down to expose the bars for bonding it with pile cap. Such provision of in-situ concrete plug serves better for transferring the vertical load from pile cap to pile. This arrangement is suitable where lateral loads acting on the structure are insignificant.

Fig. 2 – Typical Connection between Pile and Pile Cap