Engineering work for projects culminates in shaping the vision and dream of the designers into reality through construction and commissioning of the facilities. For most projects, the customer who invests in the project is the beneficiary of the commercial benefits accruing from the added or improved facility. On rare occasions, projects opportunities arise which provide direct benefits to the community adversely affected in disasters. Successful completion of such projects which can bring back smile on the faces of people who have lost valuable possessions during calamities provide an unparalleled level of satisfaction. This article presents the case study on the rehabilitation project work undertaken by Tata Group in Uttarakhand in the aftermath of Kedarnath flood where TCE partnered the project. The work highlights the unique experience of the project team in executing the challenging task in difficult terrain, with acute logistics problems, using local and often poorly skilled resources but the unique opportunity of bringing some happiness back into the lives of the people is a heart-warming experience.

Introduction

The Tata Uttarakhand Programme (TUP) is aimed at providing immediate relief and long-term benefit to the people of Uttarakhand who suffered in the disaster of the Kedarnath flood in June 2013. The program was designed for aid of 6,000+ households in 63 villages across 3 districts in the state. The theme of the rehabilitation programme was reconstruction of facilities for education and livelihood. The key elements included building public infrastructure in form of schools, anganwadi centres and a weaving centre. The program is executed by Tata Relief Committee (TRC) with Tata Consulting Engineers (TCE) providing the engineering support.

Rehabilitation Program details

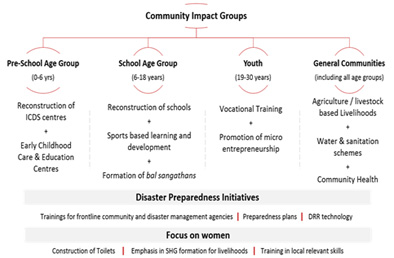

The following figure shows the basic scheme of the rehabilitation framework for TUP.

The rehabilitation program where TCE partnered the effort of TRC consisted of construction of 8 schools, 19 anganwadi centres and 1 weaving centre being developed for construction in 26 villages in 3 programme districts. The major elements of the construction work are highlighted in the table below:

| Name / Location of School | Beneficiary | No of rooms | Built Up Area | Budgetary Cost | Cost per Sqm area |

| (Nos) | (Nos) | (m²) | (Lacs) | (Rs) | |

| 19 Anganwadi Centres at different villages | 285 | 19 | 440 | 220 | 28000 |

| Government Inter College (GIC) at Baram (Pithrogarh) | 556 | 19 | 2,192 | 414.45 | 18907 |

| GIC at Mawani Dhawani (Pithoragarh) | 335 | 06 | 678 | 165.00 | 24336 |

| GIC at Munsiari (Pithoragarh) | 160 | 11 | 717 | 153.00 | 21339 |

| GIC at Diara (Rudraprayag) | 250 | 11 | 600 | 131.67 | 21944 |

| GIC at Basukedar (Rudraprayag) | 426 | 08 | 894 | 223.62 | 25014 |

| GIC at Lamgaundi (Rudraprayag) | 326 | 06 | 476 | 121.88 | 25604 |

| Mandakini Mahila Bunkar Samiti (MMBS) Weaving Center, Lamgaundi (Rudraprayag) | 173 | 04 | 790 | 281.81 | 35672 |

| Primary School at SAARI (Rudraprayag) | 84 | 05 | 318 | 86.74 | 27277 |

| High School at Uttaron (Uttarkashi) | 250 | 12 | 1,370 | 385.24 | 28120 |

| Total | 2387 | 101 | 8255 | 2183.40 |

Design highlights

The aim of the design for the various facilities was to provide for the minimum functional requirements, basic amenities and ensure a design safe for the environmental loads. The layout plans and designs were generally based on provision of Nation Building Code. The highlights of the architectural design are listed below:

Challenges and learnings from project

The design and construction work for the various components of the project was full of challenges due to difficult terrain, restricted access, lack of skilled resources and inclement weather. Special consideration was also given to local requirements. Some of the challenges and mitigation measures adopted in design are highlighted below:

| Challenges | Mitigation measures |

| Restriction in available flat ground for proposed school buildings to accommodate play area. | Open space at roof top is planned as playing area along with seating arrangement for viewers all along the parapet wall have been considered. Appropriate live load corresponding to assembly areas have been considered at roof. |

| High seismic forces corresponding to Zone V. | The floor to floor height was optimized during the design stage to 3.30M as against initial consideration of 3.60M to reduce seismic load effect and optimize member sizes. |

| Large variation in contours posed problems for excavation and stability of cut slopes. In case of MMBS at Guptkashi, 10m high slope collapsed during heavy rain. | Random Rubble (RR) masonry and gravity wall was constructed to arrest the collapse before further construction, to render site safe for workmen |

| Most of the sites are located far away from the nearest motorable road. This has caused problems for transportation of heavy construction materials. Often the carriers had to cross rivers where only narrow footbridge existed. | Material carriage was possible only using pack animals or by manual labour. Reinforcement planning considered using lower size bars cut to required length for ease of transportation. TATA Pravesh doors and windows selected were substituted with local products to suit logistics. |

| Lack of availability of construction water sources | Water was being sourced from natural streams and springs. The sparse flow often hampered progress of work. |

| Long rainy season and unusual rainfall events | Rescheduling of activities many times |

| Lack of availability of skilled labours (mason, carpenter, blacksmith) | Skilled manpower was hired from Haldwani and Dehradun town which are about 300kms/ 250kms away from the project sites respectively. |

| Due to difficulty of access to site, excavation machines could not reach site. | All excavation work for foundation construction carried out manually. |

| Absence of testing facilities for concrete work. | To assure adherence to quality plan and quality assurance program, at insistence of TCE, tests were carried out at facility in Dehradun. This resulted in delay of construction. |

| Non-availability of local materials impaired the initial plan for use of alternative construction techniques like consolidated mud block walls and treated bamboo in the roof under-structures. | After investigation, locally available soil was found unsuitable for construction. Hence, the structures had to be built of exposed brick masonry. Similarly, the after initial trials of use of bamboo roofing structure, it was decided to limit the use of bamboo to only 3 roofs. Remaining roofs have been constructed by using steel truss. |

The major highlight of the engineering was to enable the construction of the works in safe manner, within cost, time and logistic constraints and meet the functional requirements. The basic aim of the endeavour was to provide means to the people with the requirements for improving their life, especially after the loss suffered due to natural calamity which had wiped out their livelihood.

Other highlights

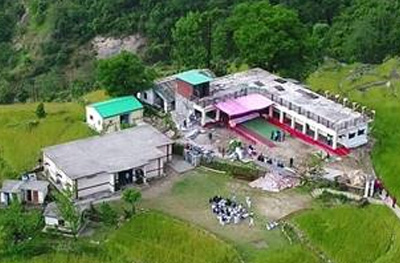

TCE has provided engineering services for design, site supervision and project management for this project under the aegis of its corporate social responsibility program. The best practices of engineering were applied for project execution and though only local contractors were employed, the quality assurance and project planning and monitoring activities were carried out diligently to ensure delivery of the highest quality. The local community participated with great eagerness to enable successful execution of the projects; in the case of the primary school at Saari, one member from each family gave a day’s ‘shramdaan’ during demolition of the old school which was completed in three days with this participation. The sense of fulfilment derived by the team working on the project of being able to give back to the community was the major driver towards excellence. The interaction with the community members, school committee members, various beneficiaries during site visits infused feeling of great pride for being part of this noble cause.

GIC Mawani Dhawani, Pithoragarh, 3D view

GIC Lamagundi

Basti Anganwadi under construction

Chaumasi Anganwadi completed

Primary School, Saari

Inauguration, MMBS, Lamagundi

Conclusion

In our role as engineering service provider, most of the projects we work on are executed by customers for increasing or improving the business. Only one rare occasion we come across opportunities to offer our knowledge and services to the community at large where we interact directly with the beneficiaries. Working on the TUP projects provided us just this opportunity where the participation and involvement with the local community throughout the project execution phase provided a unique opportunity and a chance experience the joy of giving something back to the society. The spirit of teamwork amongst the groups from different organizations of the group that came together to uphold the principle of “ONE TATA” for this noble social cause is one of the major highlights of this project.

AUTHORS

Sushil Sarangi

Manos De

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV