Digital technologies and digitalisation have touched every bit of life and have enhanced human comfort significantly over time. Large volumes of digital data generation and acquisition, a quantum leap in computation power, reliable high-speed internet, young digital-savvy workforce, industry 4.0 technologies etc., are accelerating the digitalisation in the plants. Digitalisation is making its presence felt in plant engineering and operation too. It benefits the operators in optimised energy and utility consumption, preservation of the operational know-how and practices, improvement in safety, remote monitoring, maintenance optimisation, emission control and compliance and satisfaction of operation and maintenance (O&M) staff.

Digital Transformation is a challenge and an opportunity for the engineering community to become the leading partner in this technology led transition by offering reliable digital solutions that can better plant operation and maintenance.

Digitalisation- A must for Power Sector

The power industry is undergoing rapid digitalisation among the different sectors due to the ongoing clean energy drive. Decarbonisation has become necessary to offset global climate change, and digitalisation complements the transition by technologically enabling it. The curtailment of fossil fuel-based power generation, efficiency improvement of fossil fuel-based plants and rapid shifting to renewable power sources are happening in the industry to meet the climate targets.

Digitalisation in Process Plants- Aid in Real-Time Process Optimisation

There is a focused drive in the process plants of every sector to improve yield and minimise the energy & utility consumption to run the plant optimally. Digital tools are proven to be reliable means for Real-Time Analysis and Optimisation.

Most industrial plants are instrumented adequately and generate a large amount of digital data related to complex processes. Considering the complexity of the process, continuous attention is required from the operator to run the plant optimally. The advanced digital tools can continuously monitor and provide insights into the conditions of critical equipment/processes. They can detect anomalies and provide timely alerts to the operators. The digital tools analyse the data quickly and provide the operator with valuable insights and actionable information into the processes/equipment condition, which otherwise would not be available to the operator in the plant leading to increased efficiency of the plant.

The digital PoS run on open architecture and focus on issues of specific process or equipment which are of priority. Such point solutions can be implemented quickly and independently as per requirement in a plant to take advantage of time and cost.

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV

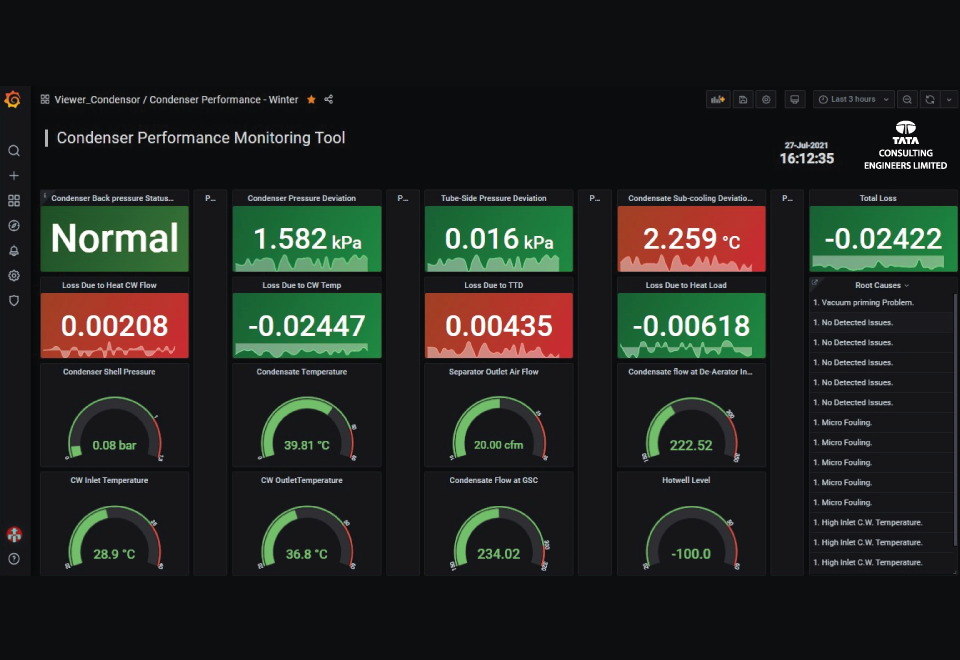

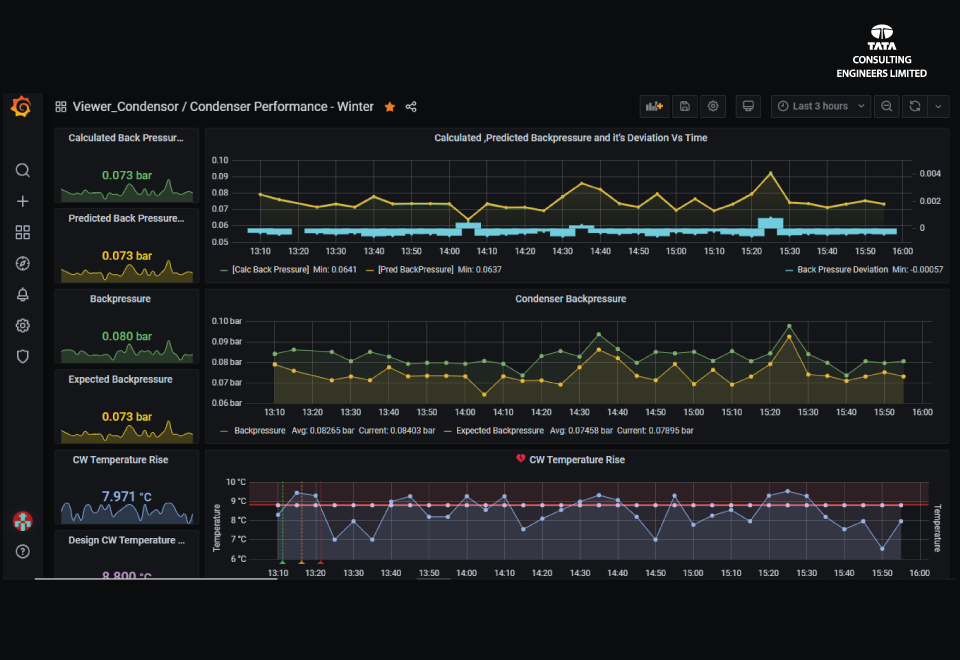

A surface condenser is a critical heat exchanger in a power plant. The performance of the condenser has a significant role in deciding the plant heat rate and efficiency. Multiple factors influence the performance of the condenser, namely, steam flow, cooling water flow, vacuum system condition, heat transfer surface etc. Degradation in performance of condenser leads to increase in heat rate, and it is difficult to find out the reasons for such performance deviation quickly. TCE’s Digital Point Solution makes this complex task easy for an operator.

A few features of the Digital Point Solution are:

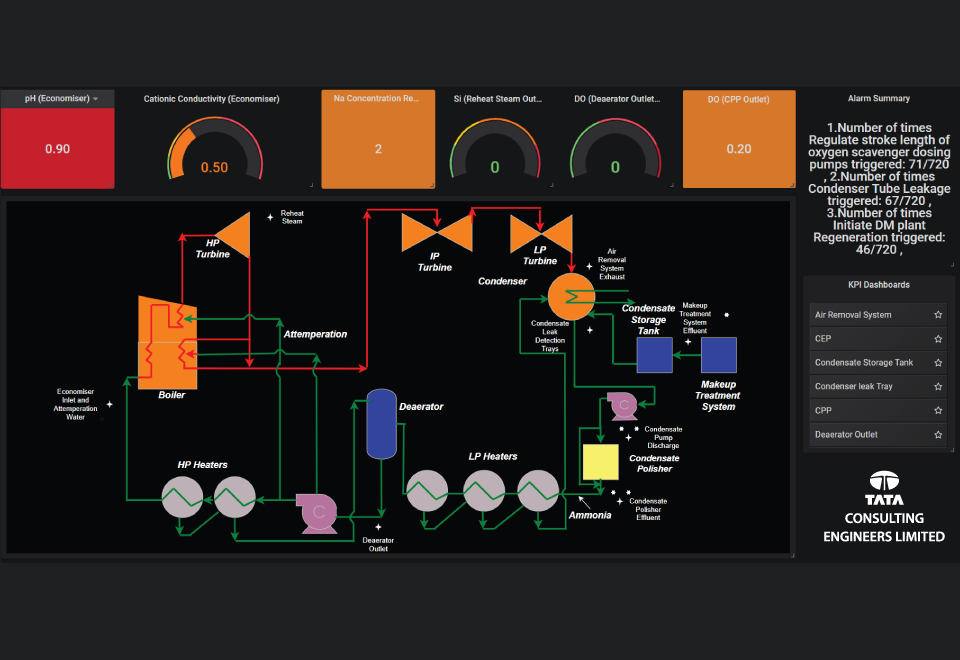

The chemistry of steam/water in a power plant influences the scaling, fouling and life cycle of various components in the feed cycle. Timely sampling, monitoring, and analysis of water/steam at selected locations are necessary to control the plant’s steam/water parameters.

With effective continuous monitoring and control of steam/water chemistry, scale deposition would be minimised. It can result in improvement of heat transfer efficiency and reduction in expensive repairs or replacement of boiler & turbine components. TCE’s Digital Point Solution can help the operator control feed water chemistry for the complete range of operations.

A few features of the Digital Point Solution are:

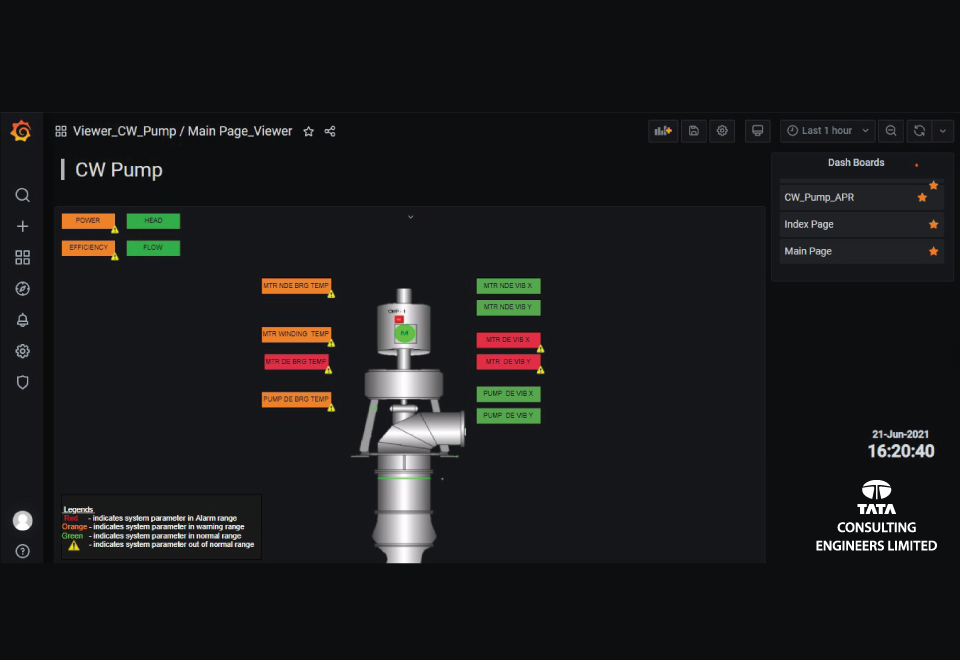

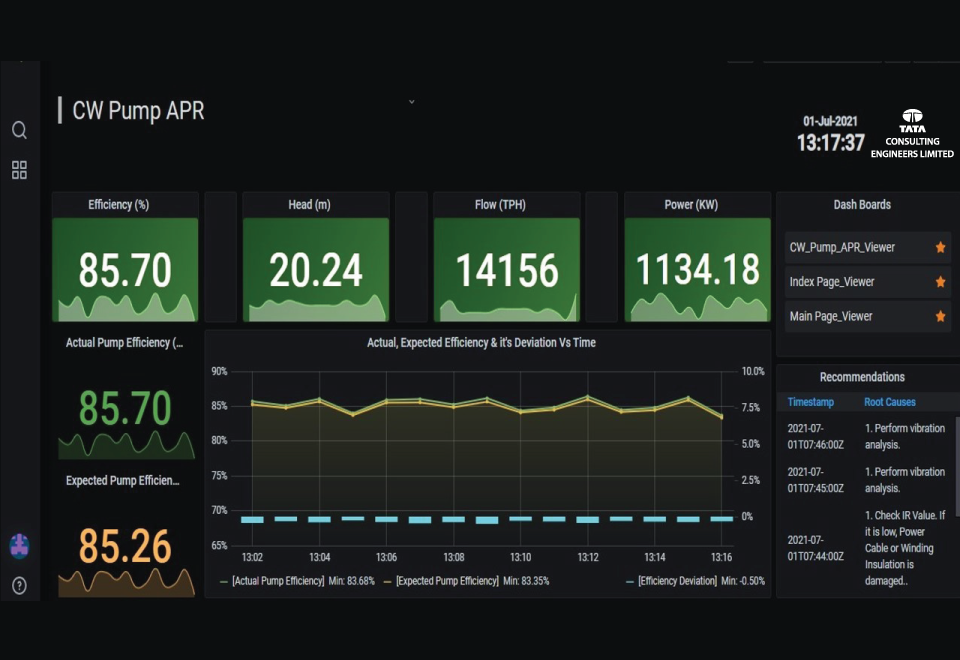

Pumps are widely used in industrial, commercial & residential applications to transfer different fluids. Performance, reliability & availability of critical pumps play a vital role in ensuring the productivity of the plants. Pumps should be operated at their Best Efficiency Point (BEP) for the best performance. But on many occasions, pumps would operate away from their BEP due to high variability in process demand and other system constraints impacting the pump’s performance and leading to higher operational costs in terms of auxiliary power.

TCE’s digital point solution can help the operator to analyse and optimise their pump performance. A few features of the Digital Point Solution are:

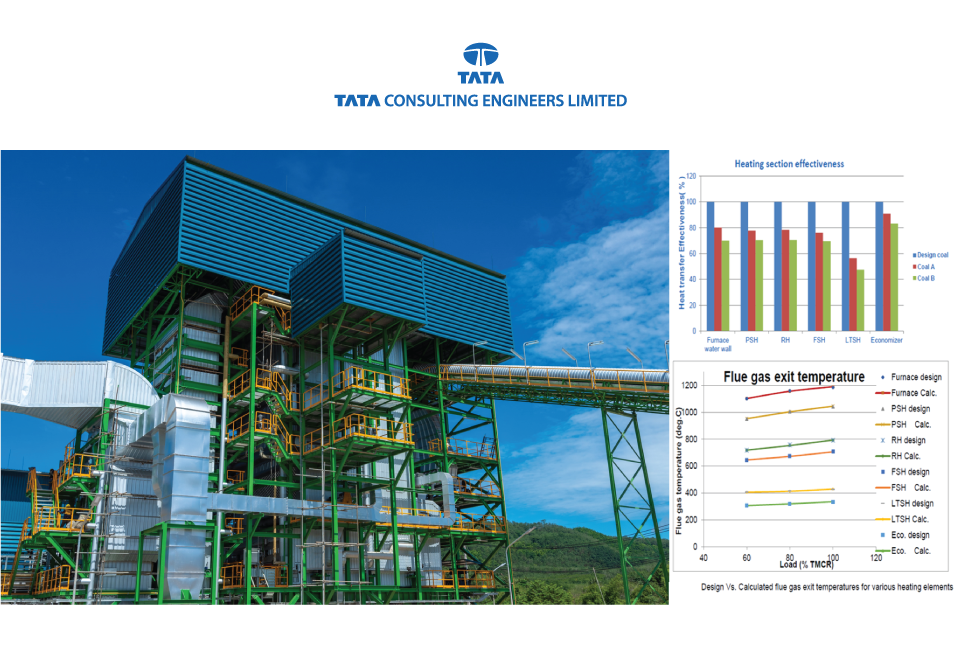

The power sector is going through a transformation phase with a focus on green power generation. A boiler is one of the critical components in a power plant. A well-designed boiler and its efficient operation are essential for better performance & reliability of a power plant.

Coal-fired power plants are designed mainly for baseload operation, are forced to operate under partial load to take care of the variable generation from renewables. Coal-fired power plants face various challenges, such as variation in coal quality and the requirement to operate flexibly at low load without compromising safety, performance, and reliability.

TCE has developed a digital point solution to predict the boiler performance with different coal quality, provide insights into the boiler operating conditions, and plan any maintenance actions.

A few features of the Digital Point Solution are:

Solar energy is the most abundant energy resource on the earth. As per the Ministry of New and Renewable Energy and the International Energy Agency, the current installed capacity of solar PV plants in India is about 35 GW, while globally, the capacity is more than 700 GW. The reliability and performance of solar PV plants shall be ensured over their lifetime. Solar PV plant operation and maintenance and its monitoring approach are evolving continuously over time.

Conventionally, the actual generation is being compared with the estimated generation. If the difference is less, it indicates a smooth operation of the plant. This conventional approach is less accurate and impacts plant Operation, Maintenance and economics.

TCE has developed a Digital point solution that can help the plant. Some features of the Point Solution are.

These features collectively can improve the reliability & availability, which helps the operator sell excess generated power in the green term ahead market to increase profitability.

Circuit breakers are critical components of power systems. The main functions of circuit breakers are switching on & switching off an electrical circuit, interrupting Short-circuit current and securing open and closed positions. Apart from the main functions, circuit breakers must behave as a good conductor during a closed position and as a good insulator during an open position.

Also, a breaker should withstand the overvoltage generated during switching and should be highly reliable during operation. Plants collect design data, operation data, maintenance data and environmental data related to a circuit breaker. Most of this data remains typically unused. In case of any abnormality or failure, the data related to the event is retrieved and analysed to find the root cause manually. This conventional approach may lead to unanticipated outages, unavailability of the system and higher maintenance costs.

TCE has developed a digital point solution that can manage a circuit breaker. Some features of the solution are:

These features of the digital point solution can help avoid unanticipated outages and unavailability of the system and reduce maintenance costs.

Cooling towers are widely used in process industries, power plants & HVAC to reject process heat into the atmosphere. In a cooling tower, most heat transfer takes place through evaporative cooling and balance by sensible cooling,

During the evaporative cooling process, water evaporates, lowering the temperature of the circulating water. Also, when the warm circulating water meets cold incoming air, sensible heat transfer occurs, causing the incoming air to heat up and the circulating water to cool down further.

An industrial cooling tower consists of static and rotating parts which can degrade over a period and may lead to thermal and mechanical performance issues. TCE has a developed digital point solution that helps the operator optimise their cooling tower performance.

The digital point solution has the following capabilities:

These features collectively improve the reliability and availability of the cooling tower, resulting in enhanced plant profitability.

Optimisation of energy consumption is the need of every industry. Fossil fuels form a significant share in the energy mix, and hence reduction of energy consumption is essential to achieve net zero-emission. Continuous monitoring of significant power consumers in a plant will help run the equipment efficiently and reduce energy consumption. Energy analytics plays a key role in minimising energy consumption by detecting the deviations and alerting the operator to take the corrective action in near real-time.

TCE has developed a digital point solution that can help the operator optimise their energy consumption.

The significant features of the Digital Point Solution are:

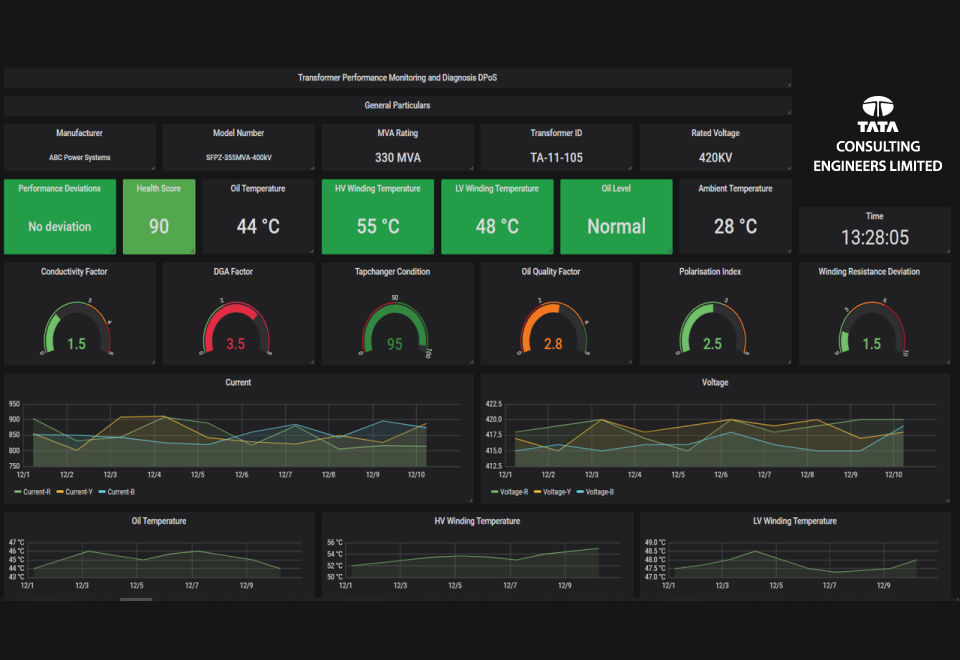

A transformer is one of the critical equipment in an electrical network system. The average life of a transformer is approximately 25 years. However, the failure rate of the transformer is on the higher side. Any fault in the transformer may reduce power system efficiency and lead to complete failure of the electric network. The significant causes of transformer failure are the deterioration of winding insulation resistance, unbalanced loading, single phasing, overloading, less maintenance, low transformer oil level, etc. As transformers are critical equipment in power transmission & distribution, monitoring the transformer’s health in real-time to avoid frequent failure is essential. The monitoring of the energy consumption will help to detect power theft and overloading.

TCE has developed a digital point solution for transformer performance monitoring and diagnosis. It will help the operator to understand the asset health & performance better and predict failures. The significant features of the Digital Point Solution are:

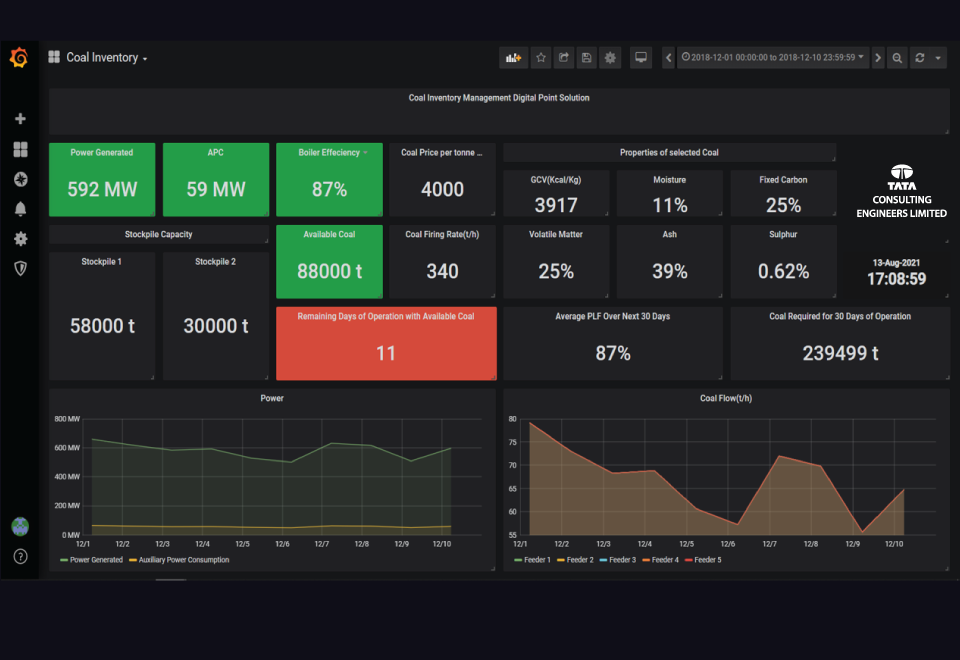

A coal handling system is an integral part of the mining as well as in power generation. It handles various fuels such as coal, lignite, pet coke. These fuels are received in a plant through various modes of transport such as rail wagons, ships, long-distance conveyors, or road trucks. The coal received at the plant is transported to the stockpile, and further, it will be reclaimed and conveyed to the consumers on demand.

The significant features of the Digital Point Solution are:

Provision for volumetric estimation of coal stockpile